You need to know about the correct pumps for effective pumping solutions. The process of choosing can be confusing quite often. You might choose the less expensive pumping solution when a specifically different pumping system could be required. Efficiency and precision can get harmed in your operations due to this. When it comes to ANSI pumps and API pumps, each of them has different applications. Hence, they work distinctively & differently. Sometimes, you may choose the more expensive API pumps when an ANSI pump could effectively work.

Rotech Pumps & Systems is a leading manufacturer & supplier of various types of pumps, mechanical seals, and valves. With an experienced team of engineers, Rotech can help you select pumps and systems based on your application needs. We will let you identify the significant differences between ANSI pumps and API pumps. First, we shall know descriptively about both types of pumps and their applications.

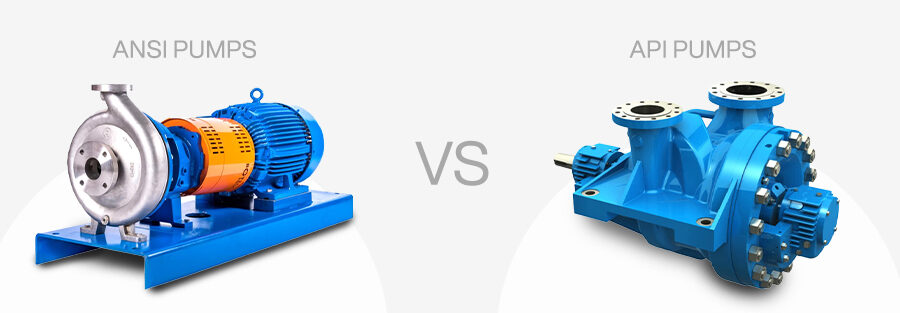

ANSI Pumps

ANSI Stands for American National Standards Institute, and ANSI Pumps are dimensionally regulated pumps. They are supposed to be horizontal, centreline discharge, and end single-stage suction. ANSI centrifugal pumps convert a motor’s mechanical energy into kinetic energy. This kinetic energy then turns into potential energy in the format of pumped fluid’s pressure which runs on a system curve with varying flow and head.

ANSI Process Pumps should meet the ANSI / ASME B73.1 standard of the American Society of Mechanical Engineers (ASME). These standards define the recommended practices and guidelines associated with the maintenance of these process pumps. It also considers alternate designs should they meet the standard’s intent and cover performance and construction-related specifications.

Applications of ANSI Pumps: ANSI pumps most frequently get used for pumping thin fluids like alcohol, water, and other less aggressive fluids.

Oil & Gas refineries, petrochemical, and chemical industries use ANSI chemical pumps. The other areas of application include paper stock, pharmaceutical, ethanol production, food processing, and many other process plants. Other industries where ANSI pumps get applied are water & wastewater management.

Benefits: ANSI pumps are cost-effective and reliable. Plant operators can easily change these pumps without redesigning or changing motor attachment, baseplate dimensions, coupling, or piping.

They have higher affordability when compared to API pumps. They also have higher availability in terms of parts and pumps.

API Pumps

API stands for American Petroleum Institute. This U.S. trade association for the oil and natural gas industries develops standards for petroleum and petrochemical equipment.

API maintains more than 500 standards and recommended practices, from drill bits to environmental protection in this industry. Differences in casings, bearing housings, mounting feet, and back cover arrangements allow API pumps to control emissions.

Applications: API Pumps get used for applications in oil refinery industries. The pumping equipment in centrifugal and positive displacement API pumps gets used in the petrochemical, gas, and petroleum industries. All of these must fulfill the requirements of the American Petroleum Institute Standard 610 for General Refinery Service.

The casings, bearing houses, mounting feet, and back cover arrangement of API pumps get designed to control emissions in a refinery and securely handle the fluids that can cause damage to the environment.

Benefits: Although API pumps are expensive and are not as flexible & readily available as ANSI pumps, they have numerous benefits.

They get built to resist higher temperatures and pressures. They are capable of handling fluids that cause environmental damage because they get designed to control emissions.

The Key Differences

ANSI standards are related to dimensions, whereas API standards are related to the pump’s construction, design, and ability to handle high temperatures and pressures. Although API pumps are heavy-duty, their applications and uses are limited to aggressive oil refinery industries.

ANSI pumps are cost-effective, long-lasting, and reliable. They are the most preferable choice for chemical processing industries. They are tremendously flexible and offer ease of operation across a massive range of applications. ANSI pumps get commonly used in food processing, pulp & paper, textiles, general manufacturing, and other generic process plants.

In conclusion, you must choose the pumping system according to the factors of applications & uses, reliability, flexibility, cost, and effectiveness. Your choice and decision should also be based on the environment of operations and the types of fluids that will get pumped. The pumps should be the best fit for your applications.

Rotech Pumps & Systems Inc. offers reliable pumping solutions according to your requirements. We are the pump people and are ready to serve you with a quick turnaround on inquiries and support.

The best part of Rotech Pumps & Systems Inc. is that they have an elaborate range of quality pumps with minimum lead times at competitive pricing. We have been a leading manufacturer of ANSI pumps and other process pumps.

1 Comment

Lily Bridgers

Because it provides dependable and effective performance for a variety of industrial applications, my dad needs to purchase an ANSI pump. It is a reliable option for his pumping needs because it complies with ANSI (American National Regulations Institute) regulations, assuring compatibility and high-quality construction. I appreciate your explaining to me why ANSI pumps are the best option for chemical processing businesses since they are affordable, dependable, and long-lasting.