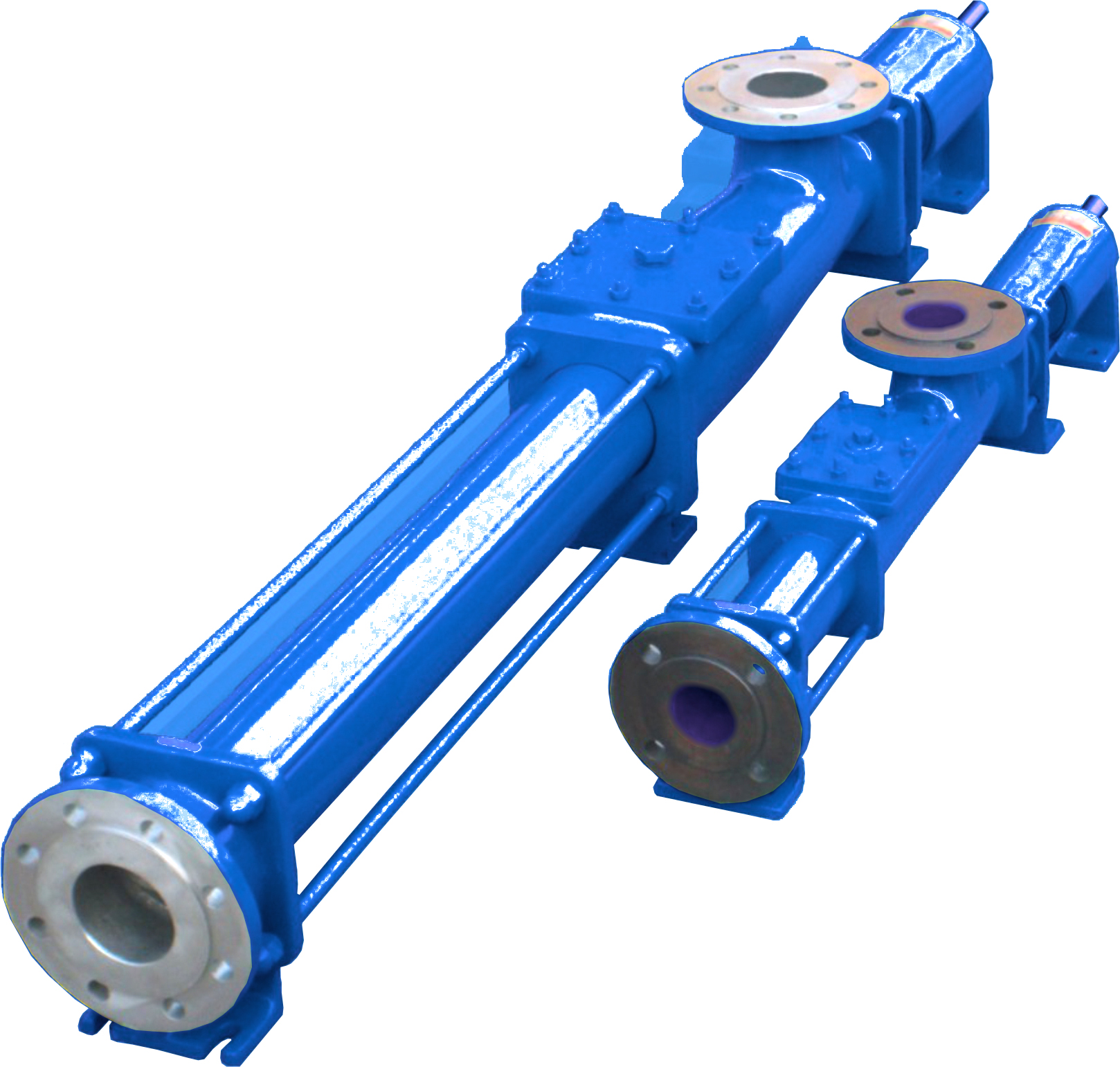

Description

Product Specification

Positive Displacement: Progressing cavities deliver a uniform, metered and non-pulsating flow. The head developed is independent, and flow rate proportion to the rotational speed.

Self-Priming: Can work on more i.e. handles high percentage of air with liquid and do not required fool valves.

Non-Clogging: Can handle solids in suspension or media containing high percentage of solids.

Low Internal Velocity: minimum degradation of shear-sensitive media and can handle highly viscous pseudo-plastic materials,

NPSH Requirements: Suction lift capacity up to 9.5 MWC and effective even in high vacuum conditions.

Reversible: Suction and Delivery ends can be interchanged by manly changing the direction of ration of the pump.

Industries to be served

Sewage

Effluent & Water Sugar,

Distillery & Brewery

Paper, Pulp & Cellulose

Ceramics & Refractories

Bulk Explosives & Emulsions Chemicals

Construction

Engineering

Fertilizer

Marine Mining

Man-made Fiber

Oil & gas

Paint & Varnish

Ship Building Industries

Design Specification

Max. Flow

Up to 880 GPM (200 m3/h)24

Max. Pressure

Up to 348 PSI (24 bar)

Max. Temperature

Up to 302°F(150°C)

Viscosity

Up to 100,000 cSt