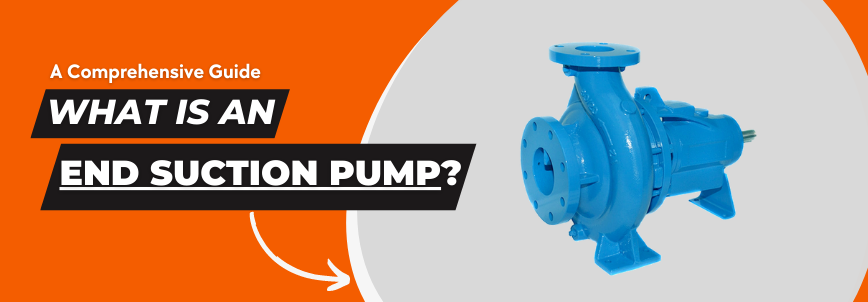

What is an end suction pump?

An end suction pump is a type of centrifugal pump that is commonly used to transfer liquids from one location to another. The pump is designed with an inlet and an outlet connection located on the same end of the pump casing. This design makes the pump easy to install and maintain, as it can be mounted horizontally or vertically with minimal piping.

The pump works by converting mechanical energy into hydraulic energy, using an impeller that rotates at high speeds. As the impeller rotates, it creates a centrifugal force that pushes the liquid towards the outer edges of the impeller blades, creating a low-pressure area at the center of the impeller. This low-pressure area draws in the liquid from the inlet connection and forces it out through the outlet connection.

End suction pumps have a long history and have been used in various forms for many years. They have evolved to become more efficient and reliable, and are now widely used in many different industries, such as water supply and distribution, HVAC and refrigeration systems, irrigation and agriculture, fire protection systems, and industrial processes. They are also used in residential applications, such as swimming pools and hot tubs.

The design and construction of end suction pumps can vary depending on the specific application. Some pumps may have a single impeller, while others may have multiple impellers. Pumps with multiple impellers are typically used for applications that require higher flow rates or higher pressure.

In this blog post, we will explore the design and construction of end suction pumps, the different types of end suction pumps, their applications, as well as maintenance and troubleshooting tips. By the end of this post, you will have a better understanding of what end suction pumps are, how they work, and where they are commonly used.

Design and Construction of End Suction Pumps:

Overview of Components:

End suction pumps are comprised of several components that work together to transfer liquids from one location to another. The primary components of an end suction pump include the casing, impeller, shaft, bearings, mechanical seals, and motor.

Casing and Impeller:

The casing of an end suction pump is the outer shell that houses the impeller and other internal components. The casing is typically made of metal or plastic and is designed to withstand the pressure and temperature of the liquid being pumped.

The impeller is the rotating component of the pump that creates the centrifugal force needed to move the liquid. The impeller is typically made of metal or plastic and is shaped to create a low-pressure area at the center of the impeller.

Shaft and Bearings:

The shaft is the component that connects the impeller to the motor and transmits the rotation of the motor to the impeller. The shaft is typically made of metal and is supported by bearings, which are located inside the casing.

The bearings support the weight of the shaft and impeller and help to reduce friction and wear.

Mechanical Seals:

Mechanical seals are used to prevent leakage of the liquid being pumped. They are typically made of carbon or ceramic and are located between the shaft and the casing. The seals create a barrier between the high-pressure liquid and the atmosphere, preventing the liquid from leaking out of the pump.

Motor and Coupling:

The motor is the component that provides the mechanical energy needed to rotate the impeller. The motor is typically an electric motor and is located outside of the casing. The motor is connected to the shaft through a coupling, which transmits the rotation of the motor to the shaft.

Overall, the design and construction of an end suction pump can vary depending on the specific application. However, all end suction pumps share similar components that work together to transfer liquids efficiently and reliably. Proper design and construction of these components are crucial to the performance and longevity of the pump.

Types of End Suction Pumps:

End suction pumps are a type of centrifugal pump that is widely used in various industrial applications. They come in three main types: close-coupled, frame-mounted, and inline. In this section, we will provide a detailed overview of each type of end suction pump.

Close-Coupled End Suction Pumps

Close-coupled end suction pumps have the motor and pump combined into one compact unit, making them easy to install and maintain. They are widely used in applications where space is limited or where a small pump is needed. The close-coupled design eliminates the need for a separate baseplate, coupling, and alignment, reducing installation time and costs. Close-coupled end suction pumps are typically used in HVAC systems, water treatment plants, and small industrial processes.

Frame-Mounted End Suction Pumps

Frame-mounted end suction pumps have the motor mounted on a separate baseplate, providing more flexibility in terms of motor size and power. They are typically used in larger applications where a higher flow rate and pressure are needed. Frame-mounted end suction pumps are also used in applications where the pump may need to be replaced or serviced without affecting the motor. Frame-mounted end suction pumps are typically used in water supply systems, wastewater treatment plants, and industrial processes.

Inline End Suction Pumps

Inline end suction pumps have a horizontal shaft and are typically used in high flow, low head applications. They are designed to be mounted in the pipeline and are used in applications where space is limited or where a compact design is needed. Inline end suction pumps are typically used in HVAC systems, water supply systems, and industrial processes.

Applications of End Suction Pumps:

End suction pumps are versatile and can be used in a wide range of applications where liquids need to be transferred efficiently and reliably. Here are some of the most common applications of end suction pumps:

Water Supply and Distribution:

It is widely used in water supply and distribution systems to transfer water from one location to another. They are used to pump water from wells, rivers, or lakes to treatment plants or directly to consumers. End suction pumps are also used in water distribution networks to maintain a constant water pressure and flow rate.

HVAC and Refrigeration Systems:

It is commonly used in heating, ventilation, and air conditioning (HVAC) systems and refrigeration systems to circulate water or other fluids. They are used to transfer heat or coolants from the HVAC or refrigeration unit to the building or equipment being cooled or heated.

Irrigation and Agriculture:

It is used in irrigation systems to transfer water from a water source to the irrigation field. They are also used in agriculture to pump water for crop irrigation, as well as for livestock watering and cleaning.

Fire Protection Systems:

End suction pumps are a critical component of fire protection systems. They are used to transfer water from a water source to the fire suppression system, which can include sprinklers, hydrants, or standpipes. End suction pumps are designed to operate at high pressures and flow rates to provide the necessary amount of water for firefighting.

Industrial Processes:

End suction pumps are widely used in various industrial processes to transfer liquids, including chemicals, petroleum products, and wastewater. In the chemical industry, they are used to transfer chemicals from storage tanks to production processes. They are also used in the petroleum industry for the transfer of crude oil, refined products, and other petroleum-based fluids. In addition, end suction pumps are commonly used in wastewater treatment plants to transfer wastewater from one stage of the treatment process to another. With their versatility and reliability, end suction pumps play a crucial role in many industrial applications.

FAQs:

What is an end suction pump?

An end suction pump is a type of centrifugal pump that is designed with a suction inlet located at the end of the pump casing. This configuration allows the fluid to be drawn into the pump through a horizontal or vertical suction pipe.

Where are end suction pumps used?

End suction pumps are used in a wide range of industrial applications, including chemical processing, oil and gas, wastewater treatment, agriculture, and HVAC systems.

How many types of end suction pumps are there?

There are several types of end suction pumps, including close-coupled end suction pumps, frame-mounted end suction pumps, and inline end suction pumps.

What are the advantages of end suction pumps?

End suction pumps are versatile, reliable, and efficient, making them an ideal choice for many industrial applications. They have a simple design that is easy to install, operate, and maintain. End suction pumps are also capable of handling a wide range of fluids, including corrosive, abrasive, and viscous liquids.

What is the difference between end suction and close-coupled pumps?

The main difference between end suction and close-coupled pumps is the way they are mounted. End suction pumps have a separate motor and are typically mounted on a baseplate or foundation. Close-coupled pumps have the motor mounted directly onto the pump and share a common shaft. Close-coupled pumps are more compact and easier to install, while end suction pumps are often more powerful and suitable for higher flow rates and pressures.

What are the limitations of end suction pumps?

End suction pumps are not suitable for all applications, particularly those that require high-head or high-pressure applications. They also have limited self-priming capabilities, which means they require a flooded suction or priming system. Additionally, end suction pumps may not be suitable for handling fluids with high solids content or highly viscous liquids. It is essential to consult with a qualified pump manufacturer or supplier to determine if an end suction pump is suitable for your specific application.